Yorkton Welding: Where It Fits Within Larger Construction Solutions

Welding is often viewed as a standalone trade, but on real job sites, it rarely works in isolation. In Yorkton, welding is usually part of something bigger—supporting construction solutions, repair work, and ongoing industrial or commercial projects.

It assists owners of projects, managers of facilities and contractors to make more informed decisions by understanding how Yorkton welding can fit in the bigger construction solutions. It also removes the need to do welding work as a last-minute job as it will most likely be effective when planned and coordinated as the work within a larger scope.

Why Welding Is Often Needed During Construction Projects

In commercial and industrial work places, welding is used in a practical manner at most part of a project. It is used in structural work, equipment installation, modification and repair which may not necessarily be evident in drawings.

Construction projects that use welding are usually required when:

- Steel elements require on site modification.

- There should be strengthening of structural connections.

- Fabrication is done on equipments or brackets.

- There are structures in existence that need to be adjusted or fixed.

Under such circumstances, welding favors development and not an independent business.

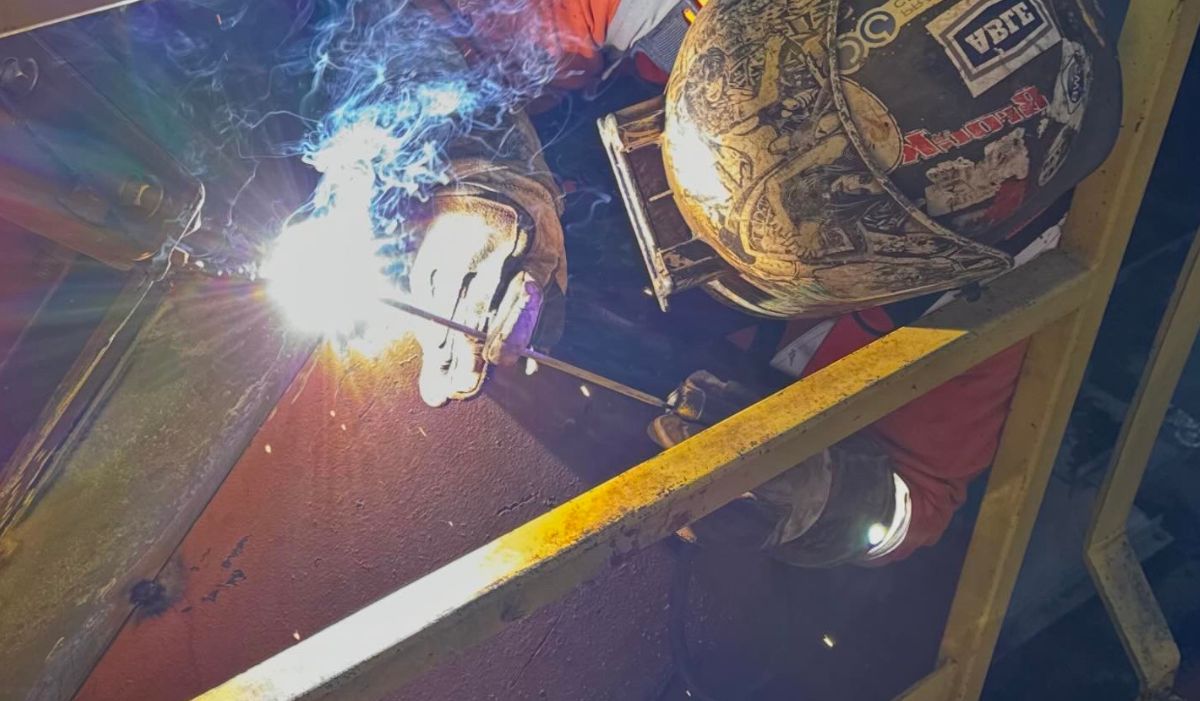

Yorkton Welding in Industrial and Commercial Environments

In industrial and commercial construction, tolerances are tighter and performance requirements are stricter. The process of welding in such an environment should be accurate, coordinated and safe.

At Yorkton, welding is more than commonly done:

- Within working industrial plants.

- On commercial construction projects having diverse trades.

- In cases where downtime is important during repair and maintenance work.

Due to these circumstances, welding has to be coupled with construction schedules, requirements of access, and safety planning.

How Welding Supports Larger Construction Solutions

Welding is most useful where this process is incorporated in larger building solutions. Rather than responding to issues when they arise, welding will also be done in the implementation of the project.

This method enables the construction teams to:

- Minimise rework due to misalignment or last minute changes.

- Maintain project momentum

- Plan ahead the use of scaffolding or lifts.

- Make sure that the welded parts are structural and operational.

In cases where welding is incorporated in the entire construction solution, it facilitates efficiency and prevents the project from stalling

The Role of Welding in Repair and Maintenance Work

Not all welding work happens during new construction. In many cases, Yorkton welding is required as part of repair and maintenance projects.

This often includes:

- Reinforcing worn or damaged steel

- Modifying existing structures to meet new requirements

- Funding equipment renovations or replacements.

- Resolving problems that are found during inspection.

Repair and maintenance welding requires careful planning, especially when work is completed in active facilities where safety and downtime are major concerns.

Why Welding Should Be Planned, Not Reactive

On a Yorkton job site, reactive welding is often the result of a “clash”—when design drawings meet the reality of existing steel. When welding is treated as a last-minute fix for parts that don’t fit, it creates a domino effect of delays.

By integrating welding into the initial Construction Solution, we address four critical variables before they become bottlenecks:

1. The Logistics of Access

In active industrial plants or tight commercial builds, you can’t just “show up and weld.” Planning ensures that scaffolding or aerial lifts are staged in sequence. Without this, a two-hour weld can turn into a two-day delay while other trades move out of the way.

2. Environmental & Site Readiness

In Saskatchewan, weather is a major technical factor. Planned welding allows for proper hoarding and heating setups during winter months, ensuring the base metal reaches the required temperatures for a structural-grade bond. Reactive welding often leads to “cold cracking” or compromised welds because the environment wasn’t controlled.

3. Trade Sequencing

Welding produces heat, fumes, and sparks (hot work). If planned, we coordinate with the HVAC and electrical teams so they aren’t pulling wire or installing sensitive components while sparks are flying. This prevents the “stop-start” rhythm that kills project momentum.

4. Quality Assurance (QA/QC)

Planned welding allows for scheduled third-party inspections and NDT (Non-Destructive Testing). When welding is reactive, the pressure to “just get it done” can lead to rushed documentation, which creates massive headaches during the final facility handover or safety audit.

Comparison: The Real Cost of Planning

| Feature | Reactive Welding (The “Fix-It” Model) | Planned Welding (The “Solution” Model) |

| Safety | High risk; requires emergency hot work permits. | Controlled; full fire watch and ventilation in place. |

| Site Impact | Stops other trades from working nearby. | Scheduled during “low-impact” windows or off-shifts. |

| Material Integrity | Potential for rushed prep and poor fitment. | Precision cuts and pre-heating for maximum strength. |

| Cost | Premium rates for emergency mobilization. | Standard project rates with predictable billing. |

Coordination Between Welding and Other Trades

Welding rarely happens alone. It often overlaps with steel installation, scaffolding, mechanical work, and equipment placement.

Effective coordination ensures:

- Welders have safe and timely access

- Other trades are not delayed

- Temporary structures are installed where needed

- Completed work is in accordance to the design and performance requirements. Trades don’t just coexist; they compete for space. Effective coordination ensures we aren’t creating a 35-foot hazard zone right where the electricians need to pull wire.

This coordination is also a major factor why welding is best integrated in the larger construction solutions as opposed to considering it as an individual activity.

Safety Considerations for Welding on Construction Sites

The process of welding at construction sites has introduced certain safety hazards such as hot work hazards, working at height, and limited access.

Safety planning of welding in commercial and industrial projects normally includes:

- Proper hot work procedures

- Controlled access zones

- Co-ordination with scaffolds or raised platforms.

- Effective communication with other trades.

Safety controls are simplified and easier to manage when welding is factored in the construction plan.

How Local Knowledge Adds Value in Yorkton

Local conditions matter. Welding in Yorkton is normally done in conditions where there are weather effects, facilities operations and constructions in the area.

Local experience helps construction teams:

- Plan welding work around site conditions

- Coordinate efficiently with other trades

- Respond quickly when site conditions change

This local knowledge reinforces the fact that with the use of welding, construction solutions are enhanced and not derailed.

When to Expect Welding as Part of a Construction Project

It is a common case that the project owners fail to understand when they require welding. It is not always so apparent in early planning.

Welding may be necessary:

- In the process of structural adjustments.

- Installation or modification of equipment.

- During repair and maintenance phases

- Where circumstances on site do not match initial plans.

This knowledge can be used to be realistic about what can be achieved and minimize end-of-the-day alterations.

Why Welding Works Best as Part of a Bigger Picture

Welding is best achieved in Yorkton when it serves a bigger purpose- ensuring that projects continue, safety is maintained and the results are consistent.

When welding is coordinated with construction solutions and repair work:

- Projects run more smoothly

- Costs are easier to manage

- Safety risks are reduced

- There is improvement in long-term performance.

This is a combined methodology to the way actual construction projects work.

Final Thoughts

Yorkton welding plays an important role in industrial and commercial construction, but its real value comes from how it fits within larger construction solutions.

Planning ahead allows your team to circumvent delays, minimize risk, and achieve better structural outcomes. Welding isn’t an isolated job—it’s the supporting role that ensures a project succeeds.

If you’re planning a project in Yorkton, don’t wait for a “clash” on the job site to think about welding. Whether you’re managing a facility upgrade or a new commercial build, integrating welding into your initial plan saves time, reduces risk, and keeps your budget on track.

Let’s look at your project together. Contact Credence Group today to discuss how our welding and construction solutions can keep your momentum moving.