What Does a Millwright Do?

What Does a Millwright Do? Understanding Their Role in Industrial Projects

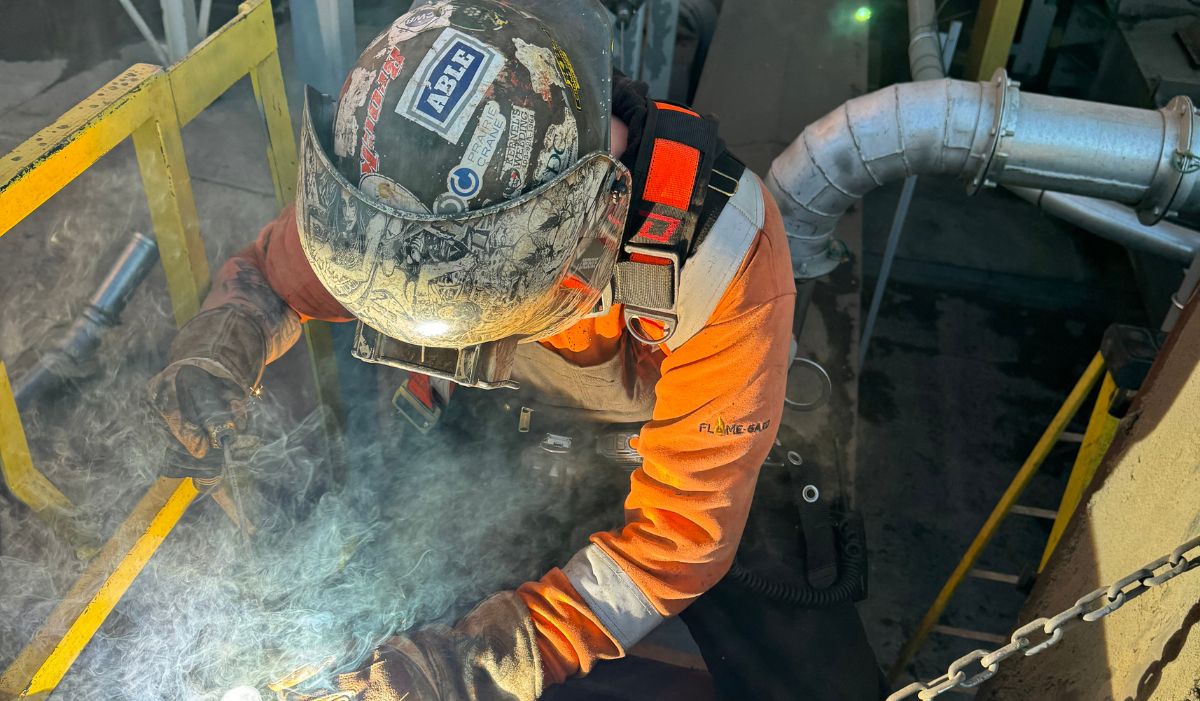

When it comes to the construction, installation, and maintenance of industrial machinery, few roles are as essential—or as misunderstood—as that of a millwright. Often working behind the scenes, millwrights are the hands-on professionals who ensure that machines operate efficiently, safely, and in alignment with technical specifications.

At Credence Construction Ltd, we’ve built a reputation for reliable millwright services across Saskatchewan and beyond. In this post, we’re breaking down what millwrights do, where they work, and why their role is crucial to industrial operations.

The Core Role of a Millwright

A millwright is a skilled tradesperson who specializes in installing, maintaining, repairing, and moving industrial machinery. This includes everything from conveyor systems in manufacturing plants to turbines in power generation facilities.

Unlike general laborers or basic mechanical technicians, millwrights work with tight tolerances, detailed blueprints, and advanced tools to ensure machinery is aligned and functioning as intended. It’s precision work that requires a deep understanding of mechanical systems, hydraulics, pneumatics, and sometimes even basic electrical components.

Key Responsibilities of a Millwright

Here are some of the core tasks millwrights handle on a day-to-day basis:

- Installation of Machinery: From anchoring machines to aligning shafts and couplings, millwrights oversee the complete setup of new equipment.

- Preventive Maintenance: Regular inspections and maintenance are essential to minimize downtime. Millwrights identify wear, replace parts, and tune up systems before problems arise.

- Repairs and Troubleshooting: When equipment fails, millwrights diagnose the issue and carry out repairs quickly and efficiently—often in high-pressure situations.

- Equipment Relocation or Upgrades: Moving or upgrading machinery isn’t as simple as lifting and shifting. Millwrights plan the relocation, disassemble systems safely, and reinstall them in the new location with precise alignment.

- Fabrication and Modifications: In some cases, they custom-fabricate parts or modify existing components to ensure systems work properly within the site’s unique requirements.

Where Do Millwrights Work?

Millwrights are found in a wide range of industries, including:

- Manufacturing plants

- Mining operations

- Agricultural processing facilities

- Pulp and paper mills

- Energy and utility companies

- Food processing and packaging plants

At Credence Construction Ltd, our millwrights are often involved in both planned maintenance and emergency breakdown support across industrial and agricultural sites. We’re also called in for large-scale construction or expansion projects, where new systems are being installed.

Why Their Work Matters

Downtime in industrial settings can be costly. A malfunctioning conveyor belt or misaligned shaft can bring an entire production line to a halt. Millwrights help reduce these risks by keeping equipment running at its best. They also play a key role in worker safety, ensuring that machines are properly secured, aligned, and safe to operate.

Their work is physically demanding, but it’s also incredibly technical. Each adjustment made by a millwright impacts not only how the machine operates, but also the broader workflow of an entire facility.

What Sets Our Millwrights Apart

At Credence Construction Ltd, our millwrights combine hands-on experience with a strong focus on safety and quality. We’re known for:

- Precision work: Whether we’re handling routine maintenance or a full equipment installation, we do the job right the first time.

- Fast response times: Industrial operations don’t wait. Our team is ready to respond to urgent breakdowns and support your team during shutdowns.

- Commitment to safety: We work in demanding environments, and safety is never an afterthought. We follow strict protocols to keep both our crew and your staff safe.

- Collaboration with other trades: Our millwrights work alongside welders, electricians, and engineers to make sure every aspect of the project runs smoothly.

Need Millwright Services in Saskatchewan?

Whether you’re planning a new installation, need emergency support, or are looking to schedule regular maintenance, our team is here to help. We work with clients across the province in industries that demand reliable, skilled tradespeople.

Contact Credence Construction Ltd to learn how our millwrights can keep your operation running smoothly—no delays, no shortcuts.